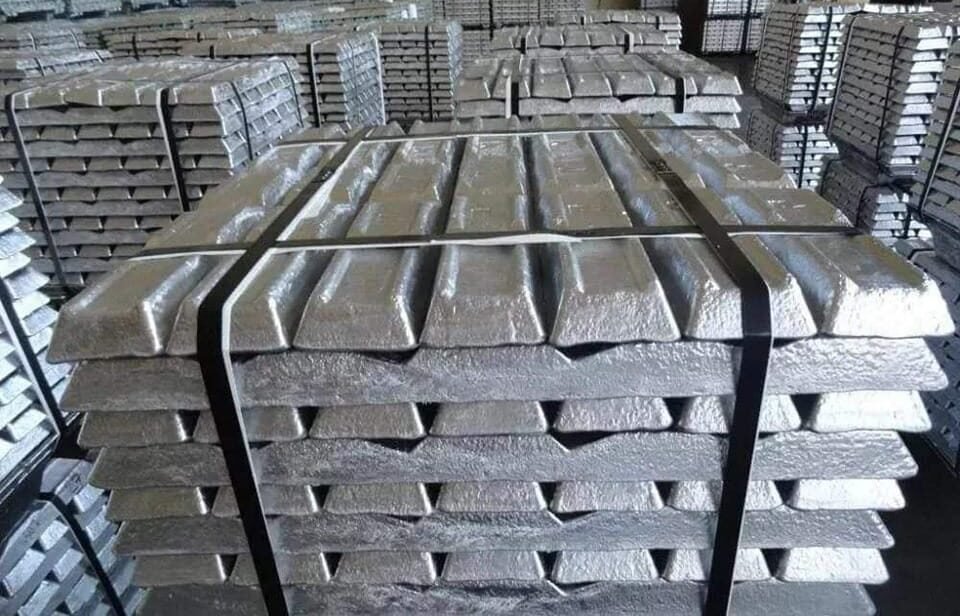

Aluminum Alloy Ingot/Aluminum ISO OEM/ODM

Aluminum Alloy ingot are manufactured from Virgin Aluminum Ingots, Semi Virgin Material and identified company-rejected scrap, thereby enabling us to give consistent quality regularly year after year. We are an environmentally conscious company; we use the best available pollution control equipment in our manufacturing process. The alloys that we manufacture go through systematic quality checks before it is dispatched to our valuable customers. Many of you may not be aware the quality of the alloy also depends on the type of Silicon Metal one uses. In our case, the Silicon Metal that is used in our alloys is sourced from companies that manufacture world-class Silicon metal using the latest German Technologies.

Aluminum Alloys Characteristics

Aluminum Alloy Ingot is a popular engineering material of choice for many applications because of the following reasons:

- Light

- Strong

- High Strength-to-Weight Ratio

- Resilient

- Ductile at Low Temperatures

- Corrosion Resistant

- Non-Toxic

- Heat Conducting

- Reflective

- Electrically Conducting

- Non-Magnetic

- Non-Sparking

- Non-Combustible

Aluminum Alloy Ingot Chemical Composition

| Alloy Type | Si % | Fe % | Cu % | Mn % | Mg % | Zn % | Pb % | Sn % | Ni % | Ti % | Additional Elements Others | Each : Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LM0 | 0.3 | 0.4 | 0.03 | 0.03 | 0.03 | 0.07 | 0.03 | 0.03 | 0.03 | – | Al 99.5 Min | – : – |

| LM2 | 9.0 – 11.5 | 1.0 | 0.7 – 2.5 | 0.5 | 0.3 | 2.0 | 0.3 | 0.2 | 0.5 | 0.2 | – | – : 0.5 |

| LM4 | 4.0 – 6.0 | 0.8 | 2.0 – 4.0 | 0.2 – 0.6 | 0.2 | 0.5 | 0.1 | 0.1 | 0.3 | 0.2 | – | 0.05 : 0.15 |

| LM5 | 0.3 0.6 | 0. | 0.3 – 0.7 | 3.0 – 6.0 | 0.1 | 0.05 | 0.05 | 0.1 | 0.2 | – | 0.05 : 0.15 | |

| LM6 | 10.0 – 13.0 | 0.6 | 0.1 | 0.5 | 0.1 | 0.1 | 0.1 | 0.05 | 0.1 | 0.2 | – | 0.05 : 0.15 |

| LM9 | 10.0 – 13.0 | 0.6 | 0.2 | 0.3 – 0.7 | 0.2 – 0.6 | 0.1 | 0.1 | 0.05 | 0.1 | 0.2 | – | 0.05 : 0.15 |

| LM12 | 2.5 | 1.0 | 9.0 – 11.0 | 0.60 | 0.2 – 0.4 | 0.8 | 0.1 | 0.1 | 0.5 | 0.2 | – | 0.05 : 0.15 |

| LM13 | 10.0 – 13.0 | 1.0 | 0.7 – 1.5 | 0.5 | 0.8 – 1.5 | 0.5 | 0.1 | 0.1 | 1.5 | 0.2 | – | 0.05 : 0.15 |

| LM16 | 4.5 – 5.5 | 0.6 | 1.0 – 1.5 | 0.5 | 0.4 – 0.6 | 0. | 0.1 | 0.05 | 0.25 | 0.2# | – | 0.05 : 0.15 |

| LM20 | 10.0 – 13.0 | 1.0 | 0.4 | 0.5 | 0.2 | 0.2 | 0.1 | 0.1 | 0.1 | 0.2 | – | 0.05 : 0.20/Td> |

| LM21 | 5.0 – 7.0 | 1.0 | 3.0 – 5.0 | 0.2 – 0.6 | 0.1 – 0.3 | 2.0 | 0.2 | 0.1 | 0.3 | 0.2 | – | 0.05 : 0.15 |

| LM22 | 4.0 – 6.0 | 0.6 | 2.8 – 3.8 | 0.2 – 0.6 | 0.05 | 0.15 | 0.1 | 0.05 | 0.15 | 0.2 | – | 0.05 : 0.15 |

| LM24 | 7.5 – 9.5 | 1.3 | 3.0 – 4.0 | 0.5 | 0.3 | 3.0 | 0.3 | 0.2 | 0.5 | 0.2 | – | – : 0.50 |

| LM25 | 6.5 – 7.5 | 0.5 | 0.2 | 0.3 | 0.2 – 0.6 | 0.1 | 0.1 | 0.05 | 0.1 | 0.2# | – | 0.05 : 0.15 |

| LM26 | 8.5 – 10.5 | 1.2 | 2.0 – 4.0 | 0.5 | 0.5 – 1.5 | 1.0 | 0.2 | 0.1 | 1.0 | 0.2 | – | 0.05 : 0.15/Td> |

| LM27 | 6.0 – 8.0 | 0.8 | 1.5 – 2.5 | 0.2 – 0.6 | 0.35 | 1.0 | 0.2 | 0.1 | 0.3 | 0.2 | – | 0.05 : 0.15 |

| LM28* | 17.0 – 20.0 | 0.7 | 1.3 – 1.8 | 0.6 | 0.8 – 1.5 | 0.2 | 0.1 | 0.1 | 0.8 – 1.5 | 0.2 | Cr 0.6, Co 0.5 | 0.10 : 0.30 |

| LM29* | 22.0 – 25.0 | 0.7 | 0.8 – 1.3 | 0.6 | 0.8 – 1.3 | 0.2 | 0.1 | 0.1 | 0.8 – 1.3 | 0.2 | Cr 0.6, Co 0.5 | 0.10 : 0.30 |

| LM30 | 16.0 – 18.0 | 1.1 | 4.0 – 5.0 | 0.3 | 0.4 – 0.7 | 0.2 | 0.1 | 0.1 | 0.1 | 0.2 | – | 0.10 : 0.30 |

| LM31+ | 0.25 | 0.5 | 0.1 | 0.1 | 0.5 – 0.75 | 4.8 – 5.7 | 0.05 | 0.05 | 0.1 | 0.25# | Cr 0.4 – 0.6 | 0.05 : 0.15 |

| ALSI – 62 | 5.5 – 7.0 | 0.4 | 1.8 – 2.5 | 0.2 – 0.6 | 0.3 – 0.7 | – | – | – | – | 0.2 | – | BAL |

| ALSI – 132 | 11.0 – 12.5 | 1.0 | 1.75 – 2.5 | 0.5 | 0.3 | 1.4 | 0.1 | – | 0.3 | 0.1 | – | BAL |

Notes:

1. Single figures in this table are the maximum value

2. To determine whether a composition found by analysis conforms to the requirements of the specification, the analytical figure should be rounded off to the nearest unit in the last right-hand place of figures used in the corresponding limits in the table (according to BS 1957)

3. In cases where alloys are required in the modified condition, the level of any modifying element present is not limited by the specified maximum value for other elements

# 0.05% minimum if Titanium alone is used for grain refining

* LM28 and LM29 are also subject to metallographic structure requirements

+ LM31 castings in the M condition have to be naturally aged for 3 weeks before use or before determination of mechanical properties

| Alloy Designation | Si % | Fe % | Cu % | Mn % | Mg % | Zn % | Ni % | Ti % | Pb % | Sn % | Cr % | Al % | Other Elements | Others Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1900 | 0.5 | 0.6 | 0.2 | 0.2 | 0.05 | 0.1 | 0.1 | – | 0.05 | 0.05 | – | 99.0 Min | – | – |

| 1950 | 0.3 | 0.4 | 0.03 | 0.03 | 0.03 | 0.07 | 0.03 | – | 0.03 | 0.03 | – | 99.5 Min | – | – |

| 2280 | 0.25 | 0.25 | 4.0 – 5.0 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 – 0.3 | 0.05 | 0.05 | – | Remainder | – | – |

| 2285 2) | 0.7 | 0.7 | 3.5 – 4.5 | 0.6 | 1.2 – 1.8 | 0.1 | 1.7 – 2.3 | 0.2 | 0.05 | 0.05 | – | Remainder | – | – |

| 2550 | 2.5 | 1.0 | 9.0 – 11.0 | 0.6 | 0.2 – 0.4 | 0.8 | 0.5 | 0.2 | 0.1 | 0.1 | – | Remainder | – | – |

| 4223 | 4.0 – 6.0 | 0.8 | 2.0 – 4.0 | 0.2 – 0.6 | 0.15 | 0.5 | 0.3 | 0.2 | 0.1 | 0.1 | – | Remainder | – | – |

| 4223A | 4.0 – 6.0 | 0.6 | 2.8 – 3.8 | 0.2 – 0.6 | 0.05 | 40.15 | 0.2 | 0.2 | 0.1 | 0.05 | – | Remainder | – | – |

| 4225 | 4.5 – 6.0 | 0.8 | 1.0 – 1.5 | 0.5 | 0.3 – 6.0 | 0.5 | 0.3 | 0.2 3) | 0.2 | 0.1 | – | Remainder | – | – |

| 4300 | 4.5 – 6.0 | 0.6 | 0.1 | 0.5 | 0.1 | 0.1 | 0.1 | 0.2 | 0.1 | 0.05 | – | Remainder | – | – |

| 4323 | 5.0 – 7.0 | 1.0 | 3.0 – 5.0 | 0.2 – 0.6 | 0.1 – 0.3 | 2.0 | 0.3 | 0.2 | 0.2 | 0.1 | – | Remainder | – | – |

| 4420 | 7.5 – 9.5 | 1.3 | 3.0 – 4.0 | 0.5 | 0.3 | 3.0 | 0.5 | 0.2 | 0.3 | 0.2 | – | Remainder | – | – |

| 4420 A | 7.5 –9.5 | 1 | 3.0 – 4.0 | 0.5 | 0.1 | 2.9 | 0.5 | – – – | – – – | 0.35 | – | Remainder | – | 0.50** |

| 4423 | 6.0 – 8.0 | 0.8 | 1.5 – 2.5 | 0.2 – 0.6 | 0.3 | 1.0 | 0.3 | 0.2 | 0.2 | 0.1 | – | Remainder | – | – |

| 4450 | 6.5 – 7.5 | 0.5 | 0.1 | 0.3 | 0.20 – 0.45 | 0.1 | 0.1 | 0.2 3) | 0.1 | 0.05 | – | Remainder | – | – |

| 4520 | 9.0 – 11.5 | 1.0 | 0.7 – 2.5 | 0.5 | 0.3 | 2.0 | 0.5 | 0.2 | 0.3 | 0.2 | – | Remainder | – | – |

| 4520 A | 9.6 – 12.0 | 1.0 | 1.5 – 3.5 | 0.5 | 0.3 | 1.0 | 0.5 | 0.3 | 0.2 | 0.2 | 0.1 | Remainder | 0.3 | – |

| 4525 | 8.5 – 10.5 | 1.2 | 2.0 – 4.0 | 0.5 | 0.5 – 1.5 | 1.0 | 1.0 | 0.2 | 0.2 | 0.1 | – | Remainder | – | – |

| 4525 A | 8.0 –11.0 | 1.3 | 2.0 – 4.0 | 0.55 | 0.1 – 0.5 | 1.2 | 1 | 0.25* | 0.35* | 0.25 | – | Remainder | 0.05 | 0.25 |

| 4528 | 8.5 – 9.5 | 0.4 – 0.6 | 1.75 – 2.5 | 0.8 | 0.15 | 0.5 | 0.8 | 0.2 | 0.1 | 0.1 | – | Remainder | – | – |

| 4600 | 10.0 – 13.0 | 0.6 | 0.1 | 0.5 | 0.1 | 0.1 | 0.1 | 0.2 | 0.1 | 0.05 | – | Remainder | – | – |

| 4600A | 10.0 – 13.0 | 1.0 | 0.4 | 0.5 | 0.2 | 0.2 | 0.1 | 0.2 | 0.1 | 0.1 | – | Remainder | – | – |

| 4628 | 11.0 – 12.5 | 0.7 – 1.1 | 1.75 – 2.5 | 0.5 | 0.3 | 1.5 | 0.3 | 0.2 | 0.05 | 0.1 | – | Remainder | – | – |

| 4635 | 10.0 – 13.0 | 0.6 | 0.1 | 0.3 – 0.7 | 0.2 – 0.6 | 0.1 | 0.1 | 0.2 | 0.1 | 0.05 | – | Remainder | – | – |

| 4652 | 10.0 – 12.0 | 1.0 | 0.7 – 1.5 | 0.5 | 0.8 – 1.5 | 0.5 | 0.7 – 1.5 | 0.2 | 0.1 | 0.1 | – | Remainder | – | – |

| 5230 | 0.3 | 0.6 | 0.1 | 0.3 – 0.7 | 3.0 – 6.0 | 0.1 | 0.1 | 0.2 | 0.05 | 0.05 | – | Remainder | – | – |

| 5500 | 0.25 | 0.4 | 0.1 | 0.1 | 9.5 – 11.0 | 0.1 | 0.1 | 0.2 | 0.05 | 0.05 | – | Remainder | – | – |

Notes:

1. Designations shall be as given in IS 6051

2. Chromium content in this alloy shall not exceed 2 percent

3. If present, titanium content shall be less than 0.05 percent

4. Other impurities do not preclude the possible presence of other unnamed elements. However analysis shall regularly be made only for the impurities listed in the table. The major element (Aluminum) shall be determined by difference between the sum of total elements analysed (& permitted within maximum limits) and 100 percent. By agreement between manufacturer and purchaser, analysis may be required and limits established for elements not specified

‘*’ If required by the purchaser only and in such case, the limits shall be as per the agreement between purchaser and the supplier and the maximum limits shall be as specified in the table

‘**’ Sum of all other elements each having value of 0.010% or more.’

Aluminum Alloy Ingot Chemical Composition – (Japanese Standard JIS H 5302:2006)

| Alloy Type | Si % | Fe % | Cu % | Mn % | Mg % | Zn % | Ni % | Ti % | Pb % | Sn % | Cr % | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ADC1 | 11.0 – 13.0 | 1.3 | 1.0 | 0.3 | 0.3 | 0.5 | 0.5 | 0.3 | 0.2 | 0.1 | – | BAL |

| ADC3 | 9.0 – 10.0 | 1.3 | 0.6 | 0.3 | 0.4 – 0.6 | 0.5 | 0.5 | 0.3 | 0.15 | 0.1 | – | BAL |

| ADC5 | 0.3 | 1.8 | 0.2 | 0.3 | 4.1 – 8.5 | 0.1 | 0.1 | 0.2 | 0.1 | 0.1 | – | BAL |

| ADC6 | 1.0 | 0.8 | 0.1 | 0.4 – 0.6 | 2.6 – 4.0 | 0.4 | 0.1 | 0.2 | 0.1 | 0.1 | – | BAL |

| ADC10 | 7.5 – 9.5 | 1.3 | 2.0 – 4.0 | 0.5 | 0.3 | 1.0 | 0.5 | 0.3 | 0.2 | 0.3 | – | BAL |

| ADC12 | 9.6 – 12.0 | 1.3 | 1.5 – 3.5 | 0.5 | 0.3 | 1.0 | 0.5 | 0.3 | 0.2 | 0.3 | – | BAL |

| ADC12Z | 9.6 – 12.0 | 1.3 | 1.5 – 3.5 | 0.5 | 0.3 | 3.0 | 0.5 | 0.3 | 0.2 | 0.3 | – | BAL |

| ADC14 | 16.0 – 18.0 | 1.3 | 4.0 – 5.0 | 0.5 | 0.5 – 0.65 | 1.5 | 0.3 | 0.3 | 0.2 | 0.3 | – | BAL |

| AC1A | 1.2 | 0.5 | 4.0 – 5.0 | 0.3 | 0.15 | 0.3 | 0.05 | 0.25 | 0.05 | 0.05 | 0.05 | BAL |

| AC1B | 0.03 | 0.35 | 4.2 – 5.0 | 0.1 | 0.15 – 0.35 | 0.1 | 0.05 | 0.05 – 0.3 | 0.05 | 0.05 | 0.05 | BAL |

| AC2A | 4.0 – 6.0 | 0.8 | 3.0 – 4.5 | 0.55 | 0.25 | 0.55 | 0.3 | 0.2 | 0.15 | 0.05 | 0.15 | BAL |

| AC2B | 5.0 – 7.0 | 1.0 | 2.0 – 4.0 | 0.5 | 0.5 | 1.0 | 0.35 | 0.2 | 0.2 | 0.1 | 0.2 | BAL |

| AC3A | 10.0 – 13.0 | 0.8 | 0.25 | 0.35 | 0.15 | 0.3 | 0.1 | 0.2 | 0.1 | 0.1 | 0.15 | BAL |

| AC4A | 8.0 – 10.0 | 0.55 | 0.25 | 0.3 – 0.6 | 0.3 – 0.6 | 0.25 | 0.1 | 0.2 | 0.1 | 0.05 | 0.15 | BAL |

| AC4B | 7.0 – 10.0 | 1.0 | 2.0 – 4.0 | 0.5 | 0.5 | 1.0 | 0.35 | 0.2 | 0.2 | 0.1 | 0.2 | BAL |

| AC4C | 6.5 – 7.5 | 0.55 | 0.25 | 0.35 | 0.25 – 0.45 | 0.35 | 0.1 | 0.2 | 0.1 | 0.55 | 0.1 | BAL |

| AC4CH | 6.5 – 7.5 | 0.2 | 0.2 | 0.1 | 0.2 – 0.4 | 0.1 | 0.05 | 0.2 | 0.05 | 0.05 | 0.05 | BAL |

| AC4D | 4.5 – 5.5 | 0.6 | 1.0 – 1.5 | 0.5 | 0.4 – 0.6 | 0.3 | 0.2 | 0.2 | 0.1 | 0.05 | 0.15 | BAL |

| AC5A | 0.6 | 0.8 | 3.5 – 4.5 | 0.35 | 1.2 – 1.8 | 0.15 | 1.7 – 2.3 | 0.2 | 0.05 | 0.05 | 0.15 | BAL |

| AC7A | 0.2 | 0.3 | 0.1 | 0.6 | 3.5 – 5.5 | 0.15 | 0.05 | 0.2 | 0.05 | 0.05 | 0.15 | BAL |

| AC7B | 0.2 | 0.3 | 0.1 | 0.1 | 9.5 – 11.0 | 0.1 | 0.05 | 0.2 | 0.05 | 0.05 | 0.15 | BAL |

| AC8A | 11.00 – 13.0 | 0.8 | 0.8 – 1.3 | 0.15 | 0.7 – 1.3 | 0.15 | 0.8 – 1.5 | 0.2 | 0.05 | 0.05 | 0.1 | BAL |

| AC8B | 8.5 – 10 – 5 | 1.0 | 2.0 – 4.0 | 0.5 | 0.5 – 1.5 | 0.5 | 0.10 – 1.0 | 0.2 | 0.1 | 0.1 | 0.1 | BAL |

| AC8C | 8.5 – 10.5 | 1.0 | 2.0 – 4.0 | 0.5 | 0.5 – 1.6 | 0.5 | 0.50 | 0.2 | 0.1 | 0.1 | 0.1 | BAL |

| AC9A | 22.0 – 24.0 | 0.8 | 0.5 – 1.5 | 0.5 | 0.5 – 1.7 | 0.2 | 0.50 – 1.5 | 0.2 | 0.1 | 0.1 | 0.1 | BAL |

| AC9B | 18.2 | 0.8 | 0.5 – 1.6 | 0.5 | 0.5 – 1.8 | 0.2 | 0.50 – 1.0 | 0.2 | 0.1 | 0.1 | 0.1 | BAL |

Aluminum Alloy Ingot Chemical Composition – (US Standard)

| ANSI | UNS | Si % | Fe % | Cu % | Mn % | Mg % | Zn % | Ni % | Ti % | Pb % | Al % |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 201.2 | A02012 | 0.1 | 0.1 | 4.0 – 5.2 | 0.2 – 0.5 | 0.2 – 0.55 | – | – | – | – | BAL |

| 204.2 | A02042 | 0.15 | 0.1 – 0.2 | 4.2 – 4.9 | 0.05 | 0.2 – 0.35 | 0.05 | 0.03 | 0.15 – 0.35 | – | BAL |

| 208.1 | A020B1 | 2.5 – 3.5 | 0.9 | 3.5 – 4.5 | 0.5 | 0.1 | 1.0 | 0.35 | 0.15 – 0.25 | – | BAL |

| 208.2 | A020B2 | 2.5 – 3.5 | 0.8 | 3.5 – 4.6 | 0.3 | 0.03 | 0.2 | – | 0.25 | – | BAL |

| 222.1 | A02221 | 2.0 | 1.2 | 9.2 – 10.7 | 0.5 | 0.2 – 0.35 | 0.8 | 0.5 | 0.2 | – | BAL |

| 241.1 | A02421 | 0.7 | 0.8 | 3.5 – 4.5 | 0.35 | 1.3 – 1.8 | 0.35 | 1.7 – 2.3 | 0.25 | 0.25 | BAL |

| 242.2 | A02422 | 0.6 | 0.6 | 3.5 – 4.5 | 0.1 | 1.3 – 1.8 | 0.1 | 1.7 – 2.3 | 0.25 | – | BAL |

| A242.1 | A12421 | 0.6 | 0.6 | 3.7 – 4.5 | 0.1 | 1.3 – 1.7 | 0.1 | 1.8 – 2.3 | 0.2 | 0.15 – 0.25 | BAL |

| A242.2 | A12422 | 0.35 | 0.6 | 3.7 – 4.6 | 0.1 | 1.3 – 1.7 | 0.1 | 1.8 – 2.3 | 0.07 – 0.2 | 0.15 – 0.25 | BAL |

| 295.1 | A02951 | 0.7 – 1.5 | 0.8 | 4.0 – 5.0 | 0.35 | 0.03 | 0.35 | – | 0.07 – 0.2 | – | BAL |

| 295.2 | A02952 | 0.7 – 1.2 | 0.8 | 4.0 – 5.0 | 0.3 | 0.03 | 0.3 | – | 0.25 | – | BAL |

| 296.1 | – | 2.0 – 3.0 | 0.9 | 4.0 – 5.0 | 0.35 | 0.05 | 0.5 | 0.35 | 0.2 | – | BAL |

| 296.2 | – | 2.0 – 3.0 | 0.8 | 4.0 – 5.0 | 0.3 | 0.03 | 0.3 | – | 0.25 | – | BAL |

| 308.1 | A03081 | 5.6 – 6.0 | 0.8 | 4.0 – 5.0 | 0.5 | 0.1 | 1.0 | – | 0.2 | – | BAL |

| 308.2 | A03082 | 5.0 – 6.0 | 0.8 | 4.0 – 5.0 | 0.3 | 0.1 | 0.5 | – | 0.25 | – | BAL |

| 319.1 | A03191 | 5.5 – 6.5 | 0.8 | 3.0 – 4.0 | 0.5 | 0.1 | 1.0 | 0.35 | 0.2 | – | BAL |

| 319.2 | A03192 | 5.5 – 6.5 | 0.6 | 3.0 – 4.0 | 0.1 | 0.1 | 0.1 | 0.1 | 0.25 | – | BAL |

| 328.1 | A03281 | 7.5 – 8.5 | 0.8 | 1.0 – 2.0 | 0.2 – 0.6 | 0.25 – 0.6 | 1.5 | 0.25 | 0.2 | 0.25 | BAL |

| 332.1 | A03321 | 8.5 – 10.5 | 0.9 | 2.0 – 4.0 | 0.5 | 0.6 – 1.5 | 1.0 | 0.5 | 0.25 | – | BAL |

| 332.2 | A03322 | 8.5 – 10.0 | 0.6 | 2.0 – 4.0 | 0.1 | 0.9 – 1.3 | 0.1 | 0.1 | 0.25 | – | BAL |

| 333.1 | A03331 | 8.0 – 10.0 | 0.8 | 3.0 – 4.0 | 0.5 | 0.1 – 0.5 | 1.0 | 0.5 | 0.2 | – | BAL |

| 336.1 | A03361 | 11.0 – 13.0 | 0.9 | 0.5 – 1.5 | 0.35 | 0.8 – 1.3 | 0.35 | 2.0 – 3.0 | 0.25 | – | BAL |

| 336.2 | A03362 | 11.0 – 13.0 | 0.9 | 0.5 – 1.5 | 0.1 | 0.9 – 1.3 | 0.1 | 2.0 – 3.0 | – | – | BAL |

| 354.1 | A03541 | 8.6 – 9.4 | 0.15 | 1.6 – 2.0 | 0.1 | 0.45 – 0.6 | 0.1 | – | 0.2 | – | BAL |

| 355.1 | A03551 | 4.5 – 5.5 | 0.5 | 1.0 – 1.5 | 0.5 | 0.45 – 0.6 | 0.35 | – | 0.25 | 0.25 | BAL |

| 355.2 | A03552 | 4.5 – 5.5 | 0.14 – 0.25 | 1.0 – 1.5 | 0.05 | 0.5 – 0.6 | 0.05 | – | 0.2 | – | BAL |

| C355.2 | A33552 | 4.5 – 5.5 | 0.13 | 1.0 – 1.5 | 0.05 | 0.5 – 0.6 | 0.05 | – | 0.2 | – | BAL |

| 356.1 | A03561 | 6.5 – 7.5 | 0.5 | 0.25 | 0.35 | 0.25 – 0.45 | 0.35 | – | 0.2 | – | BAL |

| 356.2 | A03562 | 6.5 – 7.5 | 0.13 – 0.25 | 0.1 | 0.05 | 0.3 – 0.45 | 0.05 | – | 0.25 | – | BAL |

| 357.1 | A03571 | 6.5 – 7.5 | 0.12 | 0.05 | 0.03 | 0.45 – 0.6 | 0.05 | – | 0.2 | – | BAL |

| A357.2 | A13570 | 6.5 – 7.5 | 0.12 | 0.1 | 0.05 | 0.45 – 0.7 | 0.05 | – | 0.04 – 0.2 | – | BAL |

| 359.2 | A03592 | 8.5 – 9.5 | 0.12 | 0.1 | 0.1 | 0.55 – 0.7 | 0.1 | – | 0.2 | – | BAL |

| 360.2 | A03602 | 9.0 – 10 | 0.7 – 1.1 | 0.1 | 0.1 | 0.45 – 0.6 | 0.4 | 0.1 | 0.15 | – | BAL |

| A360 | A0360 | 9.0 – 10 | 1.3 | 0.6 | 0.35 | 0.4 – 0.6 | 0.5 | 0.5 | – | – | BAL |

| A360.1 | A13601 | 9.0 – 10 | 1.0 | 0.6 | 0.1 | 0.45 – 0.6 | 0.4 | – | – | – | BAL |

| A360.2 | A13602 | 9.0 – 10 | 0.6 | 0.1 | 0.05 | 0.45 – 0.6 | 0.05 | – | – | – | BAL |

| 380.2 | A03802 | 7.5 – 9.5 | 0.7 – 1.1 | 3.0 – 4.0 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | – | BAL |

| A380 | A0380 | 7.5 – 9.5 | 1.3 | 3.0 – 4.0 | 0.5 | 0.3 | 3.0 | 0.5 | 0.5 | – | BAL |

| A380.1 | A13801 | 7.5 – 9.5 | 1.0 | 3.0 – 4.0 | 0.5 | 0.1 | 2.9 | 0.5 | – | – | BAL |

| A380.2 | A03602 | 7.5 – 9.5 | 0.6 | 3.0 – 4.0 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | – | BAL |

| A383 | A0383 | 9.5 – 11.5 | 1.3 | 2.0 – 3.0 | 0.5 | 0.1 | 0.3 | 0.3 | – | – | BAL |

General Uses Of Aluminum Alloy Ingot

- LM 0 Sand Castings for Electrical, Chemical, and Food Applications

- LM 2 Widely used Alloy for all Types of Die Castings

- LM 4 The most versatile Alloy with very good casting characteristics. UTS can be greatly increased after heat treatment

- LM 5 Castings required maximum resistance to corrosion such as marine components can be cast in such and chill

- LM 6 Very suitable for large intricate thin-walled castings in all types of moulds

- LM 9 Common to L.M.6 characteristics but higher U.T.S. after heat treatment

- LM 10 Suitable for sand and chill castings with high strength and shock resistance requires special foundry technique; heat treated

- LM 11 Suitable for die and centrifugal castings

- LM 12 Mainly used where a very good machined surface finished and hardness is required

- LM 13 Used in piston castings

- LM 16 Castings requiring high mechanical properties can be cast in sand or chill process

- LM 18 High resistance to corrosion with good foundry characteristics

- LM 22 Used for chill castings requiring good foundry characteristics and ductility. Requires heat treatment

- LM 24 One of the two most widely used alloys for all types of castings

- LM 25 Suitable where good resistance to corrosion combined with high strength is required

- LM 28 Piston alloy with a lower coefficient of expansion than LM 13

- LM 29 As LM 28 but the lower coefficient of expansion

- LM 30 For unlined die-cast cylinder block with low expansion and excellent wear resistance

Reviews

There are no reviews yet.